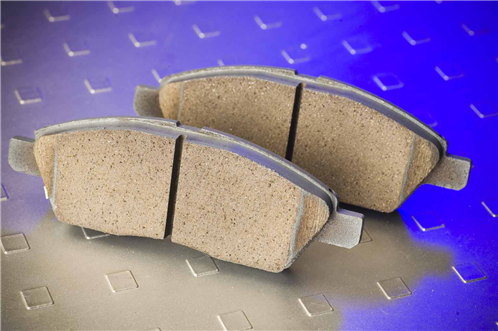

D1341 Brake Pads

Brand Feilong

Product origin China

Delivery time 30 days

Supply capacity 30000 sets/month

>100% NON-ASBESTOS MATERIAL

>PREMIUM QUALITY BRAKE PADS

>BEST STOPPING POWER IN A WIDE VARIETY OF ROAD CONDITIONS

>ENGINEERED FOR QUIET BRAKEING

>LOW DUSTING FOR CLENER WHEELS

>O.E.M MATCHED FRICTION DESIGN

>HIGH-TEMPERATURE HAVE GOOD BRAKE

Material: Semi-metal ,Low metalic, Ceramic, 100% non-asbestos

Certification: TS16949

Color: black/gray/green, or as customer's request

Accessories: Shims+ sensors+cliper+other accessories

Standard Export Package: Plastic Bag Shrink+Neutral/brand box (white, Feiroen box or customer's color box)+ Pallet

Gurantee:No noise,No dust,servic-life can rearch 30000-50000KM

Best stopping power in a wide variety of road conditions

Friction brake pad selection method

Be sure to pay attention to the following standards when purchasing brake pads. First of all, the friction coefficient of the brake pads must be appropriate. Too high will cause the wheels in the braking process to lock, the direction is out of control and the burning; if too low, the braking distance is too long.

Second, the friction brake pads produce transient high temperatures when braking, and their performance will degrade, but must be within industry standards. The normal driving range of qualified brake pads should be around 3-5 million kilometers.

The history of car friction brake pads

In 1897, the world's first brake pad was born. Then in 1909, the cured asbestos-based friction brake pads appeared. By 1968, the first semi-metal brake pads were successfully developed. Since then, the friction materials have gradually developed into non-asbestos, and various alternative materials such as steel fiber, glass fiber, aramid fiber, carbon fiber and the like have been studied at home and abroad. Due to the limited performance of a single material, modern friction materials are beginning to develop toward composite fibers.

Braking system running-in period

When the car is run-in, it is not only the engine that needs to be run-in, but also the drive system and brake system of the car. Among them, the brake system of the car needs more attention. Some cars have thicker brake pads, and the brake discs are coated with some anti-rust oil. This requires the owner to use a uniform force to step on the brakes several times to achieve the purpose of removing the brake disc oil. If the owner is driving at a speed of blind speed, in the event of an emergency, the brake system is likely to become a safety hazard. Frequent sudden braking may cause the brake pads to wear unevenly, and it may cause slight jitter and noise during braking in the future.